Description

WHAT IS OVEN TEMPERATURE LOGGER POSITEST OTL ?

Oven Temperature Logger PosiTest OTL profiles is the term used to describe the process of recording and also measuring the surface temperatures of products, and air, through the heat-treating process. Firstly temperature data is measured continuously using thermocouples connected directly to the product(s) surface at different locations. Secondly it travels through the oven or furnace, and than measured temperature readings are stored in a data logger. Which moves along with the product, and also protected from the hostile environment of the process by a thermally insulated box referred to as a thermal barrier. Either during the process “telemetry” or post-process, finally the profile data is retrieved from the data logger and transferred to a computer software package where it can review, analyzed, and reported.

Oven Temperature Data Logger

Measures and records oven temperature profiles

- Measures and also records up to 40,000 datasets (240,000 readings) into 6 independent batches

- High temperature stainless steel barrier box with fiberglass insulation for long run times at high temperatures and also contains no silicone.

- 6 K-type thermocouple ports (channels)

- Download, view, and also analyze batch data using PosiSoft Desktop Software. Export .CSV files for easy import into spreadsheets.

- Wide variety of probes available with 1.8, 3.6, or 6 m (6′, 12′, or 20′) stainless steel braided cables (sold separately)

Features

Simple

- Simple, easy-to-use interface

- 6 K-type thermocouple ports (channels)

- Measures and records up to 40,000 datasets (240,000 readings) into 6 independent batches

- Records measurements every 2 seconds for up to 22 hours of recording time

- Download, view, and also analyze batch data using PosiSoft Desktop Software. Export .CSV files for easy import into spreadsheets.

- Bright LEDs indicate logger status at a glance

- High temperature stainless steel barrier box with fiberglass insulation for long run times at high temperatures and also Contains no silicone.

- Come with Certificate of calibration showing traceability to NIST included

Specifications

Channels : 6 K-type non-grounded thermocouples

Thermocouple Measurement Range : -100 to 1000°C ( -148 to 1832°F)

Logger Operating Temperature Range PosiTest OTL without Holder or Barrier Box : 0 to 70° C / 32 to 158°F

Logger Accuracy : ±0.5° C / ±0.9° F

Resolution : 0.1° C / 0.1° F

Memory : 40,000 Datasets. Each Dataset consists of up to 6 channels.

Sample Interval : 2 seconds (Fixed) Maximum recording time is 22 hours

Power Source : 2 AAA batteries

Battery Life : 30 hours (recording time)

Size : 30.5 x 25.5 x 15 cm (12″ x 10″ x 6″)

Weight* : 9 kg (20 lbs.)*

Weight includes the PosiTest OTL Holder, and Barrier Box. Holder XT increases weight to 11 kg (25 lbs.)

OVEN TEMPERATURE DATA LOGGER KITS COME with temperature logger, stainless steel high temperature barrier box, choice of holder, 6 engraved probe ID tags, two AAA batteries, instructions, Long Form Certificate of Calibration traceable to NIST, carrying case, USB cable, PosiSoft Desktop software, and also a year warranty.

PosiTest OTL Kits

Two PosiTest Oven temperature data logger OTL Kits available…

The PosiTest OTL is available in two configurations. The PosiTest OTL XT features an enhanced holder with heat sink for greater endurance at high temperatures.

PosiTest OTL Kit & PosiTest OTL XT Kit

Temperature PosiTest OTL XT

PosiTest OTL XT (OTLKITXT) 150° C (302° F)90 minutes300 minutes200° C (392° F)65 minutes200 minutes250° C (482° F)50 minutes140 minutes300° C (572° F)not recommended100 minutes

The chart and table above represent the combined thermal characteristics of the PosiTest OTL, Barrier Box and choice of Holder/Holder XT.

1. PosiTest OTL Kit

OTLKIT with HolderView PDFAdd To Quote

2. PosiTest OTL XT Kit

OTLKITwith Holder XTView PDFAdd To Quote

Temperature Probes

Wide variety of surface and air temperature probes available with 1.8, 3.6, or 6 m (6′, 12′, or 20′) stainless steel braided cable (not included). See the Temperature Probes page for details and also Certificate of Calibration showing traceability to NIST included.

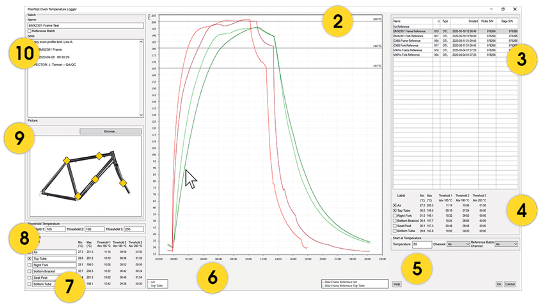

POSISOFT OTL DESKTOP

FREE powerful desktop software (PC/Mac) for downloading, viewing, printing, and alos storing measurement data available.

Add batch annotations, label individual channels, set threshold temperatures, and also compare datasets to reference batches. Includes a customizable, templated PDF Report Generator. No internet connection required.

- Customizable PDF Report Generator.

- Graph Readings for up to 6 channels and also compare to stored reference profiles.

- Store optimal cure reference profiles to compare measurement results.

- Select one or more reference channels to plot alongside measurement data.

- Start At Temperature sets the time to 00:00 when the selected channel reaches the threshold temperature, making it easier to compare logged batch results with reference data.

- Use cursor to hover and identify individual channels (traces).

- Rename channels.

- Add up to 3 Threshold Temperatures to calculate Time above Temperature.

- Add an image to identify probe placement.

- Add imagery and notes to any report.

WHY RECORD TEMPERATURE PROFILE

During the powder coating process, the applied powder coating must be exposed to elevated temperatures for a predetermined amount of time to cure properly.

Frequent oven profiling is required to control the curing process

- Firstly is ensure powder coatings are fully cured

- Secondly is minimize energy costs related to unnecessarily high oven temperatures or long run times

- Finally is include oven profile tests in process control procedures

We also provide other powder coatings related inspection instrument in one line such as:

The First is PosiTest OTL Oven Temperature Logger

Secondly is PosiTector 6000 Digital Coating Thickness Gage for ALL Metal Substrates

Third is PosiTest DFT Economical Coating Thickness Gage for ALL Metal Substrates

Forth is DeFelsko powder-comb Uncured Powder Thickness for All Substrate

Finally is PosiTest PC Non-contact Uncured

TQC SHEEN CURVE X 4 OVEN TEMPERATURE DATA LOGGER.

Profiling an industrial powder coating oven starts here with the CurveX 4 Oven Logger Kit. It contains all necessary items, just add the desired magnetic or clamp-type probes to make the oven logger kit complete.

The main component of the kit is the CurveX 4 Oven Data Logger which offers easy-to-use and also high quality temperature data logging for coating curing ovens. Measurements, analysis levels and also report options are fully customizable to provide you with tailor-made information on the quality of your curing processes.

The oven temperature data logger is placed in an insulated box and as it moves through the oven with the work piece and it can measure the temperature in several places on the surface of the product simultaneously. Up to 8 probes for measuring the air or surface temperature of the product can be connected to the data logger. The portfolio of probes includes magnet, clamp, ring-type and also wire probes.

Advanced Oven Data – Easy Return on Investment.

The CurveX 4 provides advanced oven temperature data. Combined with the Ideal Finish Analysis software, this data logger is vital for any coating curing oven – providing insights into oven temperature efficiencies, streamlining operations and also reducing operation costs.

Ideal Finish Analysis software.

The included Ideal Finish Analysis software allows you to analyze the logged temperature data and also create detailed reports. Advanced oven profiling features like cure data analysis, ideal cure and tolerance bands, together with a wide range of visualization, report and printing options, making CurveX oven logger the most flexible temperature logging solution available. Access the Ideal Finish Analysis Software here.

WHAT IS INCLUDED?

CurveX 4 Oven Logger with ideal finish analysis software, insulation box, energy absorber, silicone seal, probe idenification set and aslo a case.

Excellent suited for industrial oven and also laboratory oven temperature profiling. Mandatory test in Qualicoat, QIB and GSB accredited powder coatings.

IMPORTANCE OF OVEN PROFILING

Oven profiling has been fundamental across the coating industry, and the latest technological developments can provide production managers and also engineers powerful information about their

production processes. To guarantee finish quality, it is necessary to collect accurate information about the temperatures being experienced by a coated product throughout the oven curing process.

Each powder coating will have specific cure information (time and also temperature values), provided by coating manufacturers. In order to collect temperature information as experienced by the product, an oven temperature logger must travel with the products through the oven. This provides a complete in-process journey, profiling the oven temperatures and also its performance with real and accurate data.

Information captured by an advanced oven data logger system such as the Curve X can:

- Firstly is identify temperature fluctuations.

- Secondly is reduce energy costs and also save money – by increasing line speeds or lowering oven temperatures.

- Thirdly is optimize production processes

- Finally provides data to prove product quality and also meet specification.

Information obtained by a oven temperature system allows users to better control, understand and also optimize their oven processes, as well as ensure the highest coating quality for their finished products.

CURVE X 4 OVEN TEMPERATURE DATA LOGGER KIT IS SIMPLE. ( VIDEO )

The CurveX 4 oven logger offers easy-to-use, high quality temperature data logging for coating curing ovens. The oven data tracker is fitted with three buttons for easy operation and three LED giving power, paint type, logging and also cure information. The CurveX 4 provides advanced oven temperature data. Combined with the Ideal Finish Analysis software, this data logger is vital for any coating curing oven – providing insights into oven temperature efficiencies, streamlining operations and also reducing operation costs.

The 8-channel temperature data logger built in a sturdy aluminium and also plastic case that fulfils the needs for quality control in powder coating applications. Its ease of use and also affordable price level makes it the ideal job-coaters instrument.

Features

High Quailty temperature data logging.

CurveX Oven Logger Kit configured to start oven temperature data logging in paint and also powder coating curing oven applications – just add your probes to complete it!

Data logger includes 8 channels – with Ideal

Finish Software

Insulation box with degassed silicone materials suitable for powder coating applications

For absolutely silicone free or high temperature applications – select your insulation box.

Document and prove process quality following Qualicoat, GSB, ISO 9001, QIB etc. and create outstanding quality reports with the included advanced analysis software

Technical Specifications CurveX 4 Oven Logger

Dimensions : 110 x 85 x 35 mm

Battery Life : 35h with rechargable batteries

Measuring range : from -100°C until to 1200°C

Operating temperature : from 0°C until 60°C

Display : Three multi-colours LED’s

Memory : 20 batches with 50,000 readings

Interface : USB-C

Interval time : from 1 s to 60 min

Channels : 8 Line

Mass : 190 g / 6.7 oz

Material : Aluminium / Plastic

Accuracy : +/-1°C / 1.8°F

Power supply : Rechargeable battery.

For more product detail, information and quotation require, please contact us.